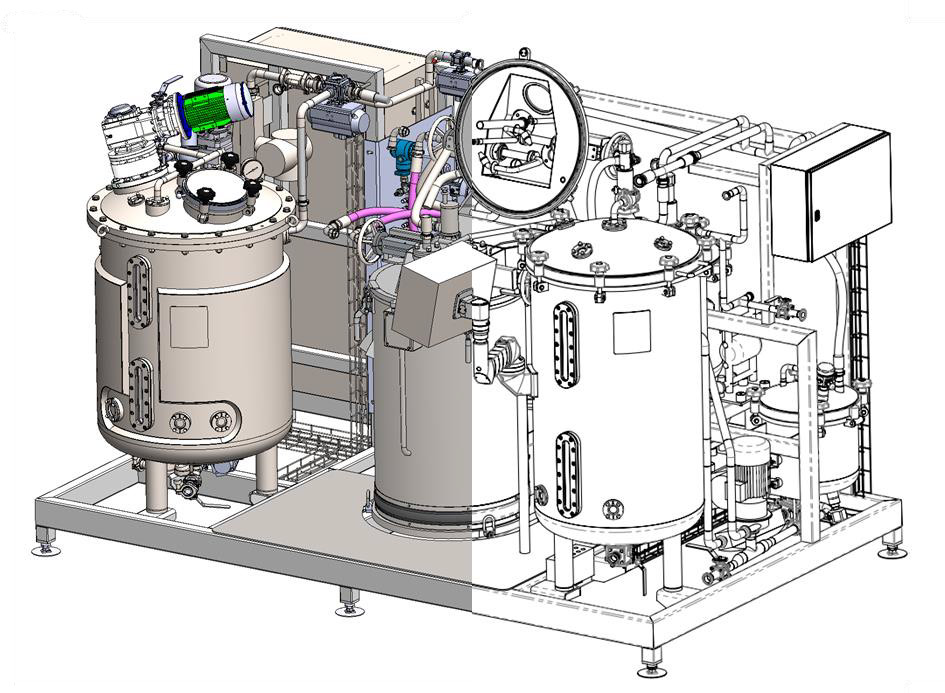

Process equipment

ARRGOS is specialised in the development and manufacture Process Equipment, Technical Solutions and Centrifuges in solid-liquid separation and liquid-liquid extraction for the pharmaceutical, chemical, biotechnology and food industries.

Our complete knowledge of the manufacturing chain enables us to implement the best technical solutions for optimised, long-lasting installations.

Thanks to its in-house skills and its parent companies, ARRGOS can support you from the expression of your needs, through design and manufacture, to commissioning.

Preliminary design

- PFD

- Preliminary design and layout study

- Risk analysis

- Dimensioning

- EMSR-planning

- Pressure loss calculation

- Inerting (flow, oxygen measurement or pressure maintenance)

- Compliance with building regulations and codes:

- PED, DESP, ASME ATEX

- cGMP

- FDA

Detail engineering

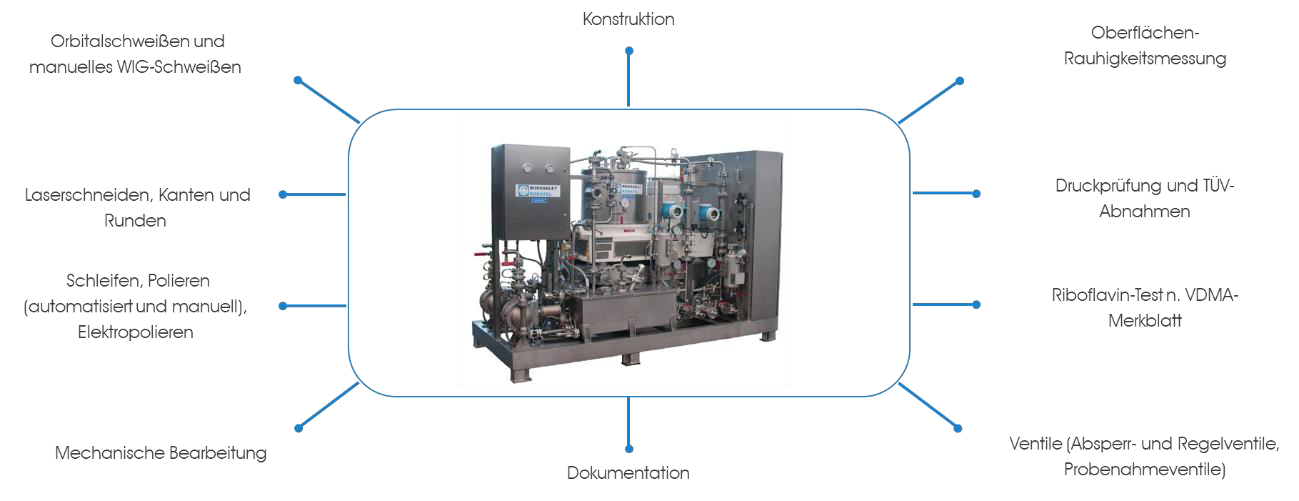

Manufacturing

- Orbital and manual TIG welding

- Plasma welding

- Laser cutting, bending and folding

- Grinding and polishing

- Electropolishing

- Pickling and passivation

- CNC machining

- Electrical wiring

- Pressure vessels

- Stainless steel piping, TIG/MIG and orbital welding

- Chassis and platform

Quality assurance and service

- Validation tests (dimensional control, pressure testing, sealing, X-ray, endoscopy, material certificates)

- Conformity testing of automation, functions and recipes

- Technical documentation

- Factory Acceptance Test (FAT) and Site Acceptance Test (SAT)

- Qualification (Design Qualification - DQ -, Installation Qualification - IQ - and Operational Qualification - OQ)

- Commissioning of process equipment and centrifuges