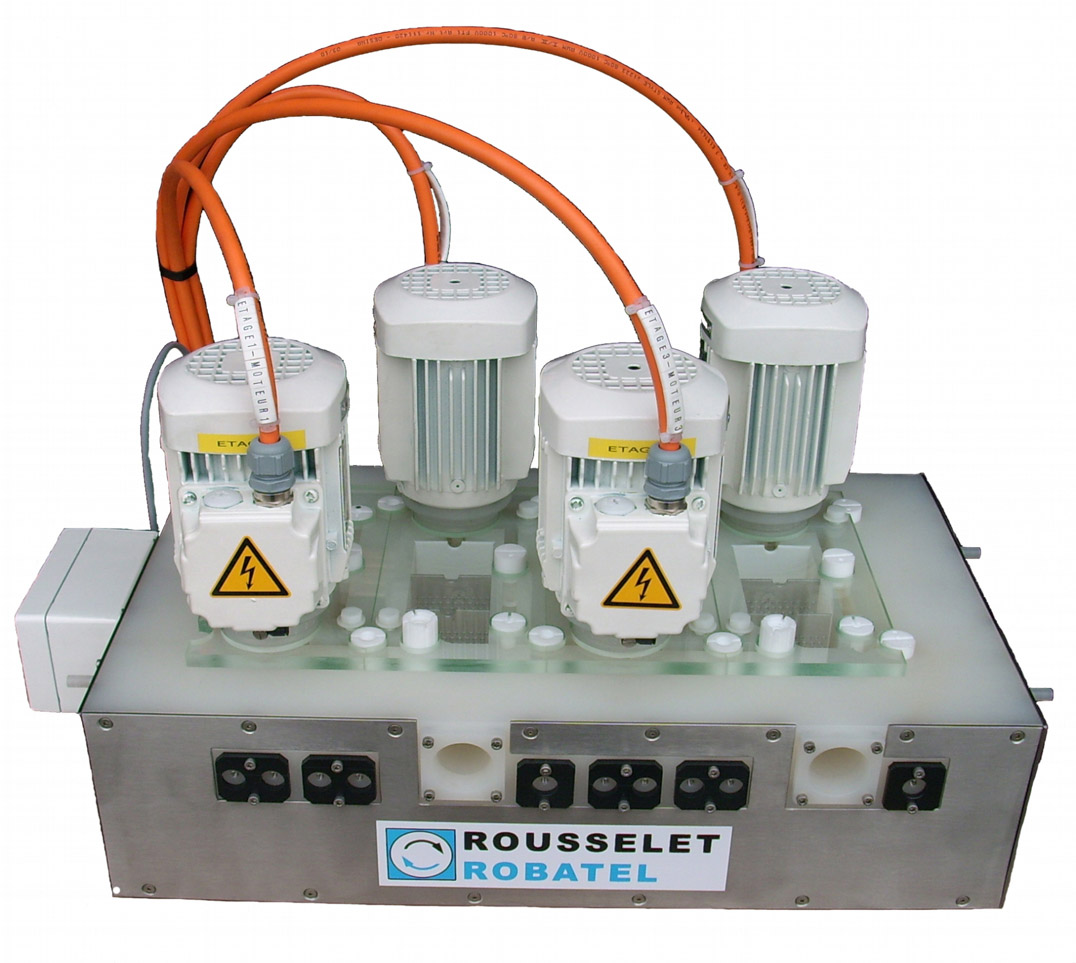

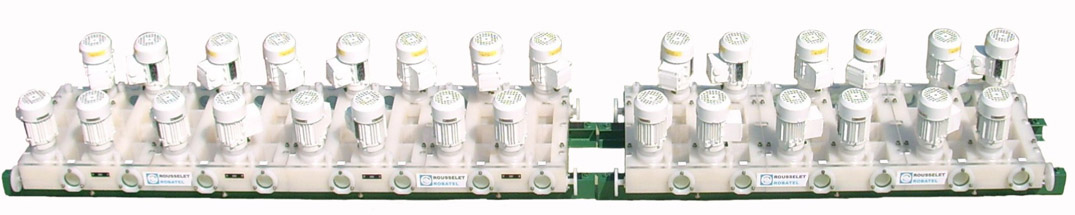

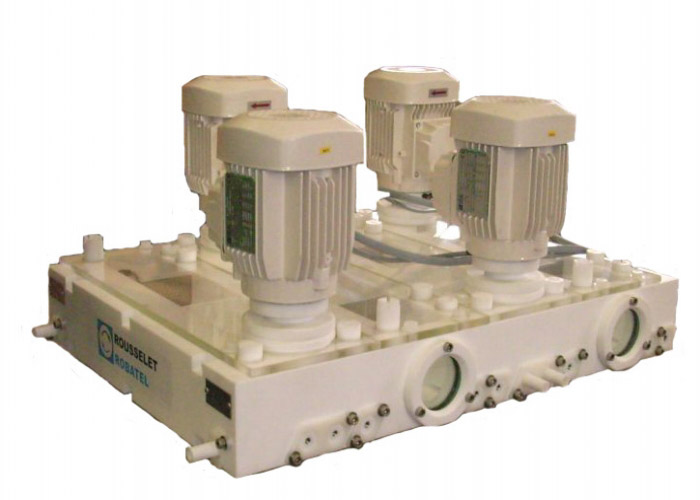

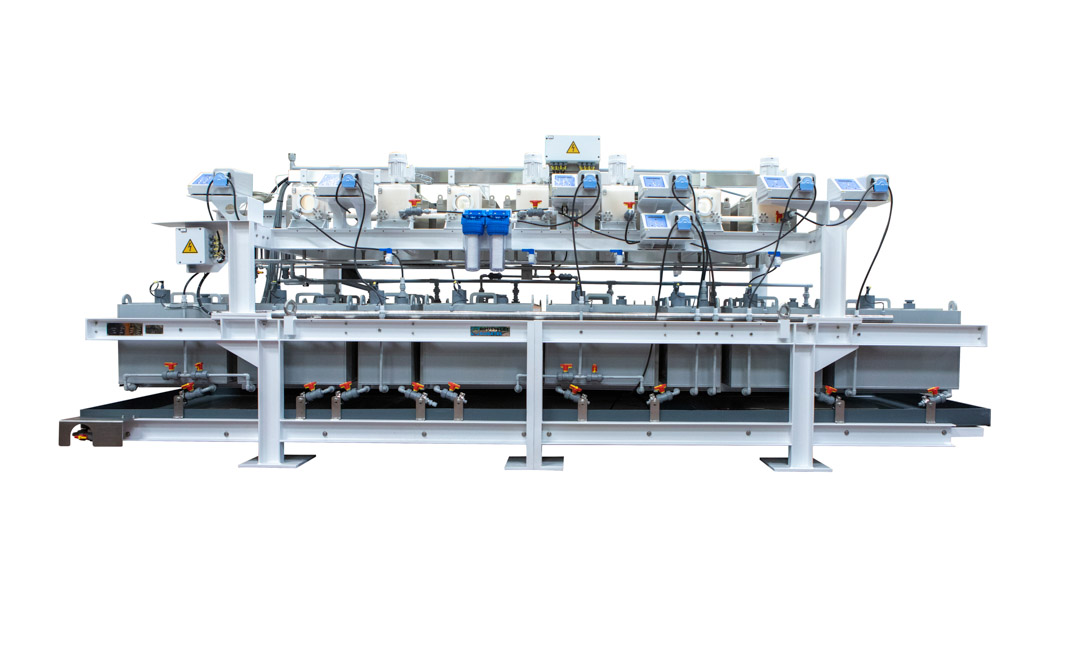

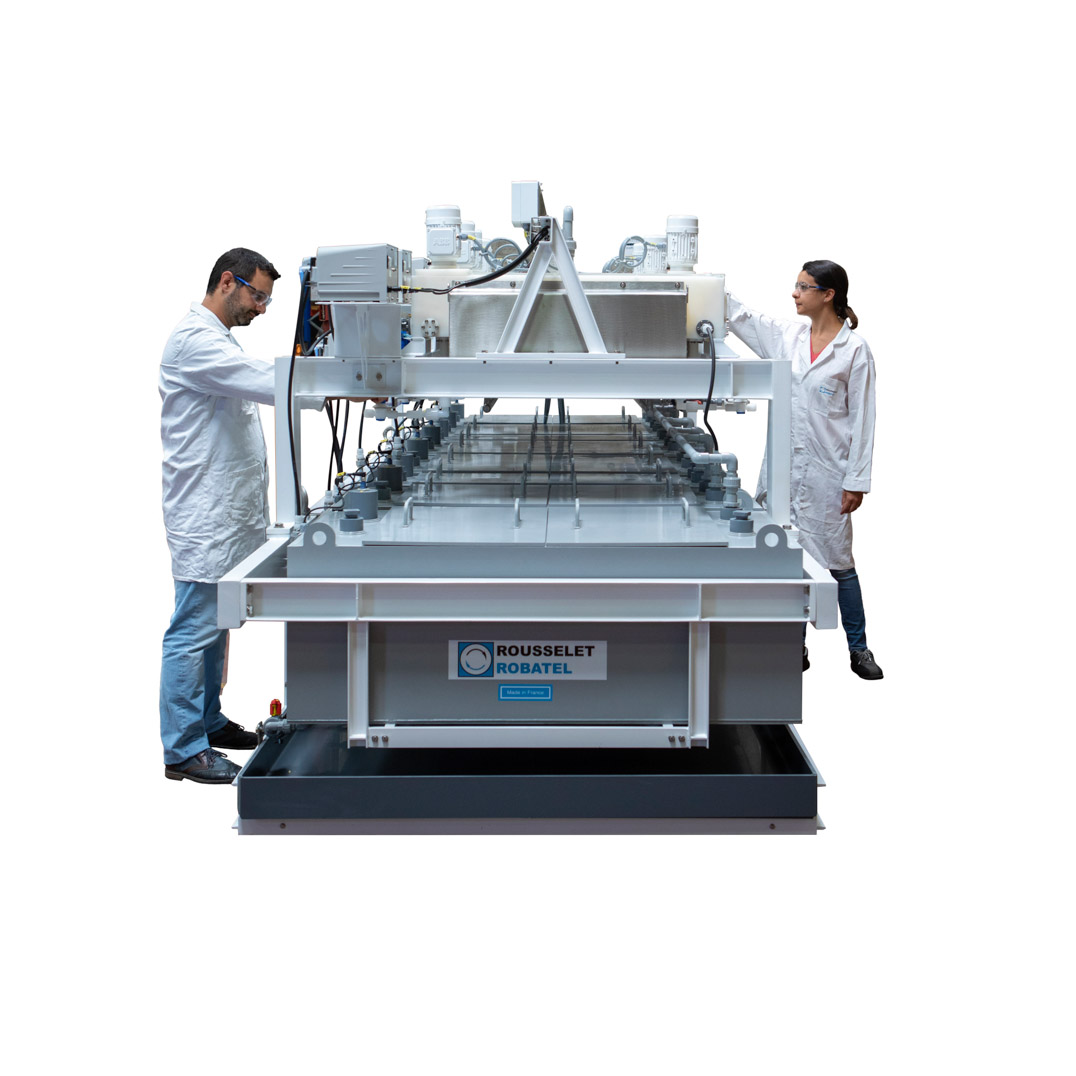

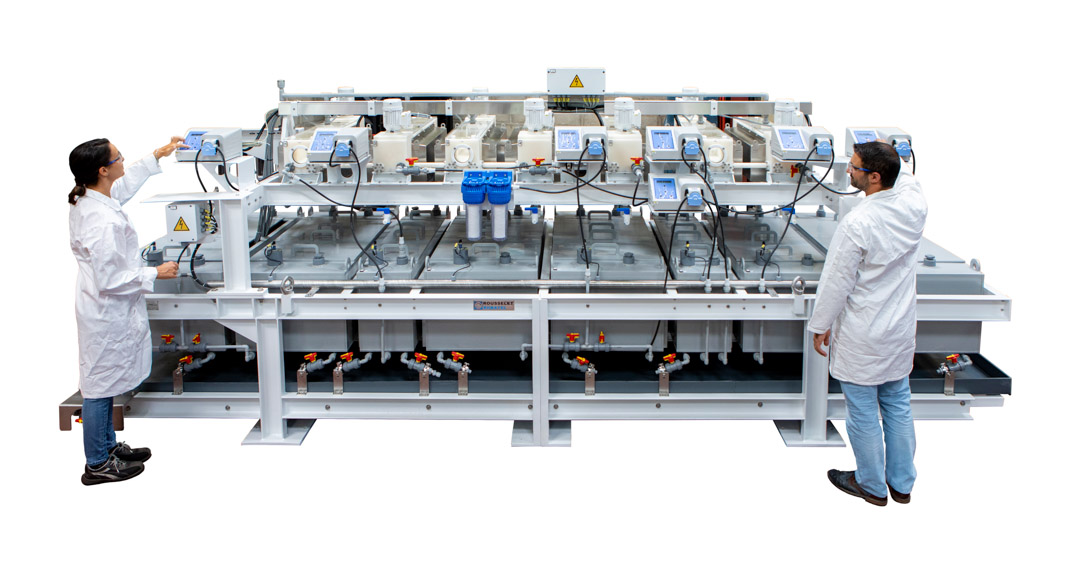

Laboratory mix spreader (mixer-settler) - Gravity

Centrifuge | liquid-liquid | Series: MD Mixer-Settler

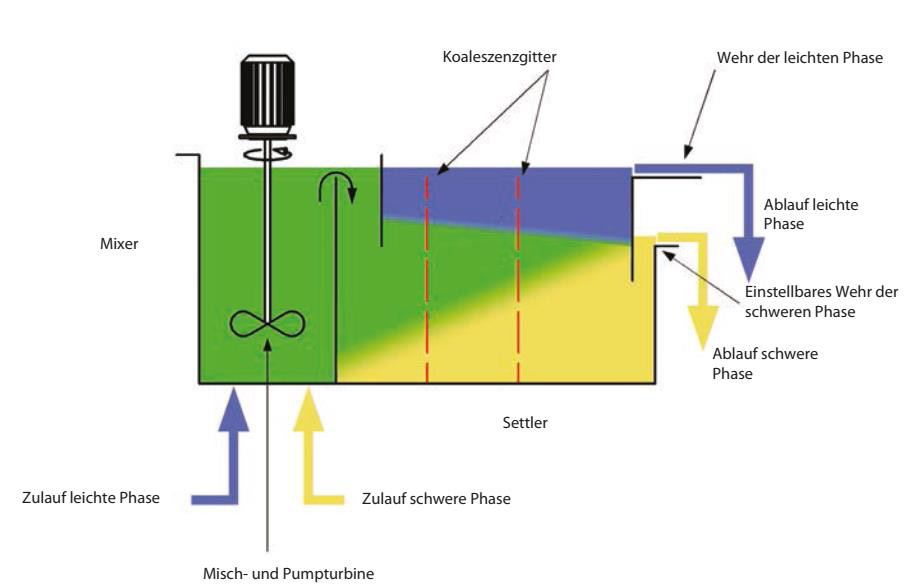

Functional description

Liquid-liquid extraction consists of transferring the solvate (or several solvates) that terminates in the primary liquid solution into another immiscible liquid (solvent). The solvent enriched with the solvate is called the extract , the diluted primary liquid solution is called the raffinate.

The primary liquid solution and the solvent are brought into contact to effect the transfer of the solvate.

The two liquid phases (extract and raffinate) are separated by static decantation (mixer-settler) or centrifugal force (ROUSSELET ROBATEL centrifugal extractors LX or BXP).

Advantages

- Continuous countercurrent extraction for maximum efficiency

- "Pump-mix" design, no intermediate pump required

- Very well suited for batch or continuous operation

- Ideal for laboratory scale extraction evaluations, R & D

- Kynar or PTFE construction for corrosive applications

- High extraction efficiency of typically more than 85% theoretical

- Connected in series to achieve the required number of stages

- Internal recycling systems

Application examples

PHARMACY: Purification of active ingredients (e.g. antibiotics).

CHEMISTRY: Washing (e.g. polymers)

- Extraction (e.g. acetic acid)

- Waste water treatment (e.g. phenol extraction from aqueous phase)

PARACHEMISTRY: perfumes, aromas, essential oils...

FOOD INDUSTRY: Purification of food components (e.g. carboxylic acid)

HYDROMETALLURGY: separation or purification (e.g. precious metals)

Main construction features

Construction material: Polyethylene, polypropylene, polyvinyl fluoride, PTFE (only for sizes 1 and 2).

Motorisation: The pump turbine is driven by a three-phase motor, protection class IP 55. Ex-proof motors on request - The motor is connected to a static frequency converter to adjust the stirring speed.

Sight glasses: fitted at the end of the settlers. Allow visual control of phase separation.

Lids: recommended to reduce evaporation of the solvent, are attached to the settler, made of glass or plexiglass (depending on size).

Size: Rousselet Robatel offers 6 battery sizes with several mixer-settler variants per size.

Phase recycling: The e-ciency of phase mixing or separation can be increased by increasing the throughput of one of the phases in relation to the other --> recycling between the settler and the mixer of the same stage.

The size 1 and 2 mixer-settlers have recycling channels equipped with change-over and control valves. In sizes 3, 4, 5 and 6, this function is fulfilled by external lines.

Intermediate, inflows and outflows: Universal mixer-settlers UX have additional inflows and outflows in each stage. A set of selectors enables the commissioning of the desired number of stages for a given battery or the division of this battery into several sections (e.g. extraction, washing, re-extraction).

Technical data MD series (mixer/settler)

| Type | Number of steps | Mixer Vol (L) | Settler Vol (L) | Decanting surface (cm2) | Throughput (L/h) |

|---|---|---|---|---|---|

| UX 1-1 | 4 | 0,035 | 0,143 | 49 | 2/4 |

| UX 1-2 | 4 | 0,05 | 0,2 | 49 | 2/5 |

| UX 1-3 | 4 | 0,035 | 0,2 | 71 | 2/5 |

| UX 1-4 | 4 | 0,05 | 0,257 | 71 | 2/6 |

| UX 2-0 | 4 | 0,2 | 1,3 | 215 | 10/20 |

| UX 2-1 | 4 | 0,2 | 1,7 | 285 | 10/20 |

| SX 3-0 | 1 | 0,62 | 3 | 270 | 15/30 |

| SX 3-1 | 1 | 0,86 | 5 | 450 | 20/40 |

| SX 4-0 | 1 | 2,3 | 11 | 1.000 | 40/80 |

| SX 5-0 | 1 | 5,2 | 21 | 1.300 | 150/200 |

| SX 5-1 | 1 | 5,2 | 36 | 2.300 | 200/300 |

| SX 6-0 | 1 | 8,5 | 29 | 1.500 | 200/300 |

| SX 6-1 | 1 | 8,5 | 50 | 2.600 | 250/400 |